Material Issue 3. Sustainable Packaging & Material Solutions

Resource circulation system:How can we build it?

HOW WE MANAGE

Plastic plays an important role in food safety, but due to the plastic, our Earth is facing serious challenges. In order to solve this, it is important to build a resource circulation system, and everyone’s determination to protect nature and society is needed to actualize the system. To fulfill a sustainable resource circulation system where we can deliver nature to our consumers’ tables and bring it back to nature, CJ CheilJedang established a packaging strategy. As a part of the strategic implementation, we are expanding collection systems to build a plastic circulation system, and expanding investments for R&D in eco-friendly packaging materials such as developing alternative materials to plastic and biodegradable materials(PHA). And by building a resource circulation system that covers all value chains, we will lead the way in reducing pollution that is caused by the use of plastic and other disposable products.

Sustainable Packaging Strategies

To expand sustainable packaging that considers nature and society, CJ CheilJedang operates a research organization, an execution organization and an eco-friendly packaging council to pursue strategic tasks throughout all stages including product planning, research and development, production, consumption, and disposal/collection through collaboration. Out of all research and development expenses for packaging, research expenses for eco-friendly packaging counts for approximately 53% of the total amount. Also, 30% of all researchers in packaging carry out duties related to eco-friendly packaging. In 2021, we expanded sustainable packaging to a variety of products, resulting in a reduction of 925 tons of raw plastic materials. We also operate an integrated sustainable packaging program and apply the newly-adopted COMPASS tool to reflect sustainability in packaging designs. For foundational improvement, we are collaborating with external partners to create technologybased systems and platforms in 2022, in addition to improving products as well as strategic tasks. In terms of R&D, various researches for ecofriendly packaging are being conducted, such as material reduction, alternative materials, recycling technology, packaging technology, etc.

Minimize the plastic & CO2 Generation

Technology

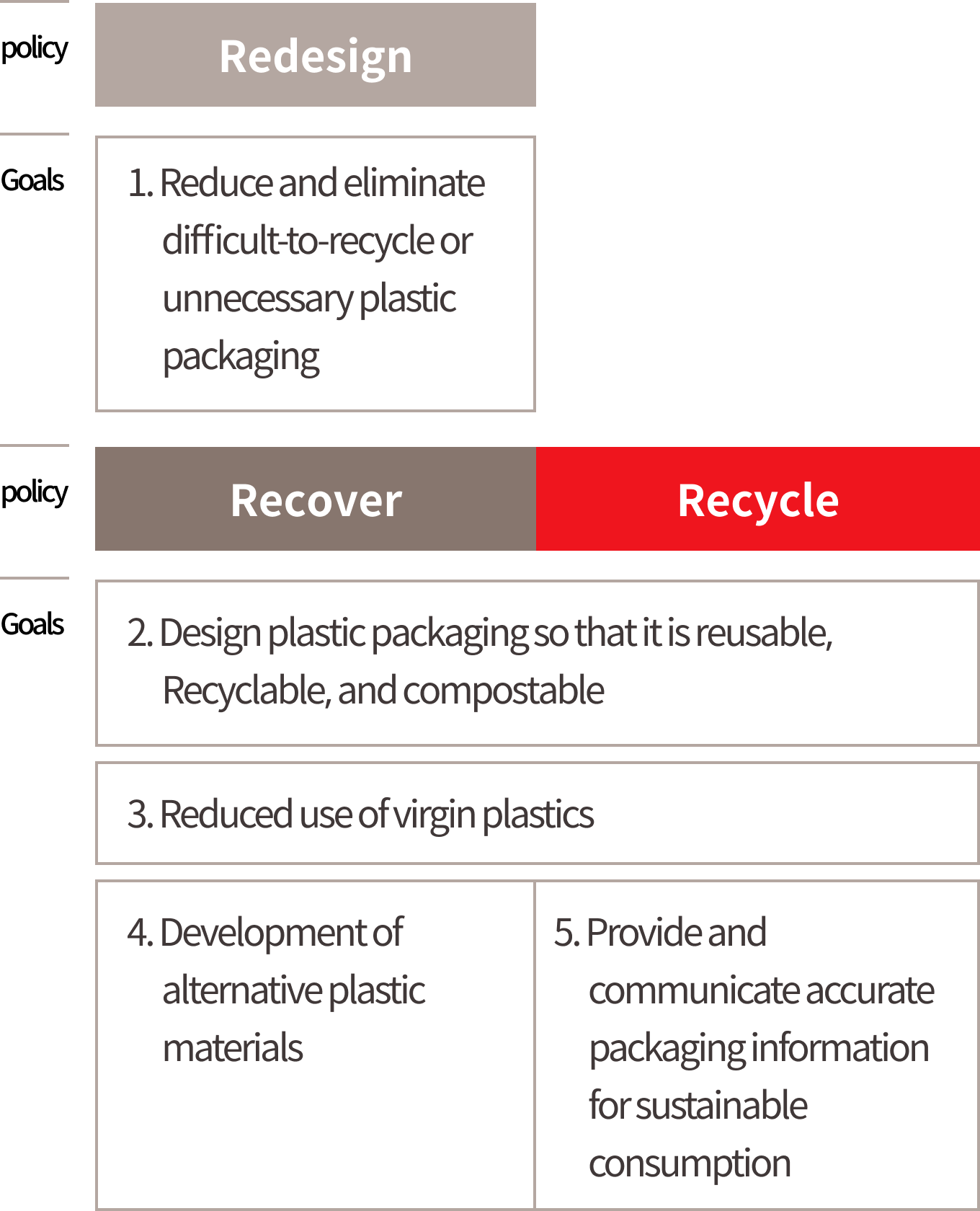

To reduce raw plastic materials and CO2 emissions, we are implementing the 3R policy(Redesign, Recover, Recycle). In eco-friendly design (Redesign), we removed unnecessary plastic materials and optimized the size and thickness of packaging materials, resulting in reduced raw plastic materials and greenhouse gas emissions. In order to minimize the environmental impact by using eco-friendly raw materials(Recover), we applied biodegradable packaging materials for the first time in Korea. In terms of recycling(Recycle), we use 50% of the scrap generated during the production of Hetbahn containers when making gift set trays. By using recycled plastic, we reduced the amount of new plastic materials used in making containers. In addition, we established an implementation plan for packaging using the 3R policy, and based on this, we are planning and executing global eco-friendly packaging projects.

Goal to reduce plastic usage in packaging

Educate The Consumer

Communication

It is necessary to raise consumers’ awareness so that consumers can properly participate in recycling after use. To this end, we support stakeholders with packaging technology, provide information on packaging handling after product use, and strive to improve recyclability.

Communicating the packaging policy with external stakeholders ㅣ CJ CheilJedang responds to inquiries from stakeholders about the use of biodegradable plastic packaging materials and plans to remove tray containers. We strive for well-rounded communication by sharing policy-related opinions based on the current status of companies in promoting plastic-free and carbon-neutral activities to support government agencies with establishing a resource circulation system. In 2021, we communicated with Green Korea, Korean Federation for Environmental Movement, Carbon Neutrality and Green Growth Commission, Korea Food Industry Association, and the Korea Chamber of Commerce and Industry.

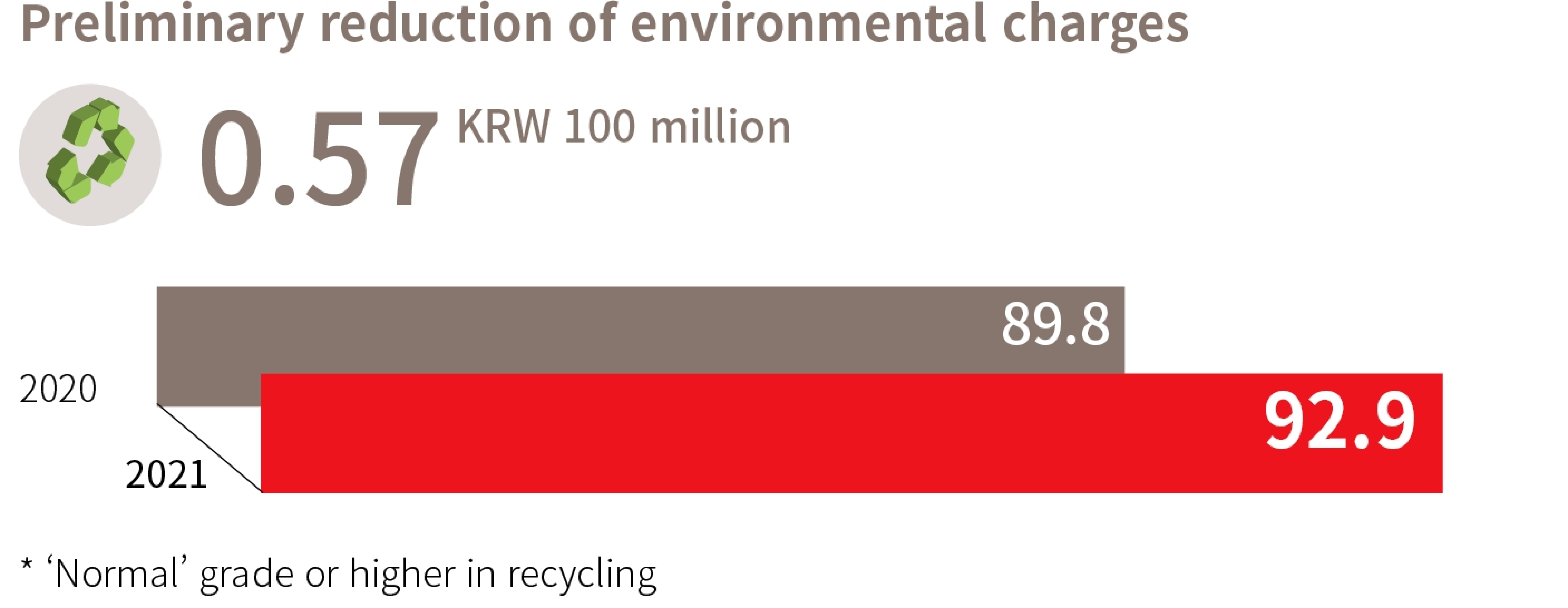

Improving the recyclability rating ㅣ In accordance with the ‘Packaging Material Recyclability Rating Standard’, we manage recycling rate of packaging material for approximately 5,000 products to improve the recyclability of packaging materials. As a result of efforts to make easier for consumers to recycle the products after use, such as inserting a perforation line on the labels of products or using a wash-off adhesives on labels/stickers, a total of 176 cases were improved in 2021, and KRW 57 million in environmental charges was reduced. We plan to continuously improve the recyclability of packaging materials from ‘normal’ to ‘excellent/best’.

Percentage of ‘Excellent’* recyclability

rating of packaging materials

Unit: %

Participated in the ‘Joint statement of global businesses for prevention of plastic pollution’

At the 5th United Nations Environment Assembly(UNEP) in March 2022, ‘End plastic pollution: Towards an international legally binding instrument’ was passed and following that, plastic regulations in each country are gradually becoming stricter. We took part in the ‘Joint statement of global businesses for prevention of plastic pollution’ in order to contribute to the establishment of international standards regarding plastic issues throughout production and consumption stages, and to pledge to work towards resolving the plastic crisis.

Increase The Collaboration

Collaboration

We are participating in domestic and international value chains and mutual cooperation networks to build a circular economy system. In 2021, we participated in the ‘Sustainability in Packaging ASIA’ as a member of the advisory committee and panel. Not only that, we strengthened our global network by participating in Foodpolis, an international food conference, Retail Future and Innovation Forum, Global packaging seminar hosted by Korea Society of Packaging Science & Technology, SPC(Sustainable Packaging Coalition), European Global Paper Consortium, and 4evergreen.

Adopting COMPASS for sustainable packaging and circular economy ㅣ In 2021, we adopted COMPASS, a packaging-related software platform developed by SPC(Sustainable Packaging Coalition) of the United States. Through this, we intend to develop eco-friendly packaging designs and contents for communication with consumers. COMPASS provides various eco-friendly data and analysis for improving sustainable packaging such as life cycle evaluation, circulation evaluation, and standards for environmental footprints of products and packaging. With this, we are measuring the performance of practical improvements made such as reduction of GHG emissions from transparent PET bottles in comparison to colored PET bottles for oil products.

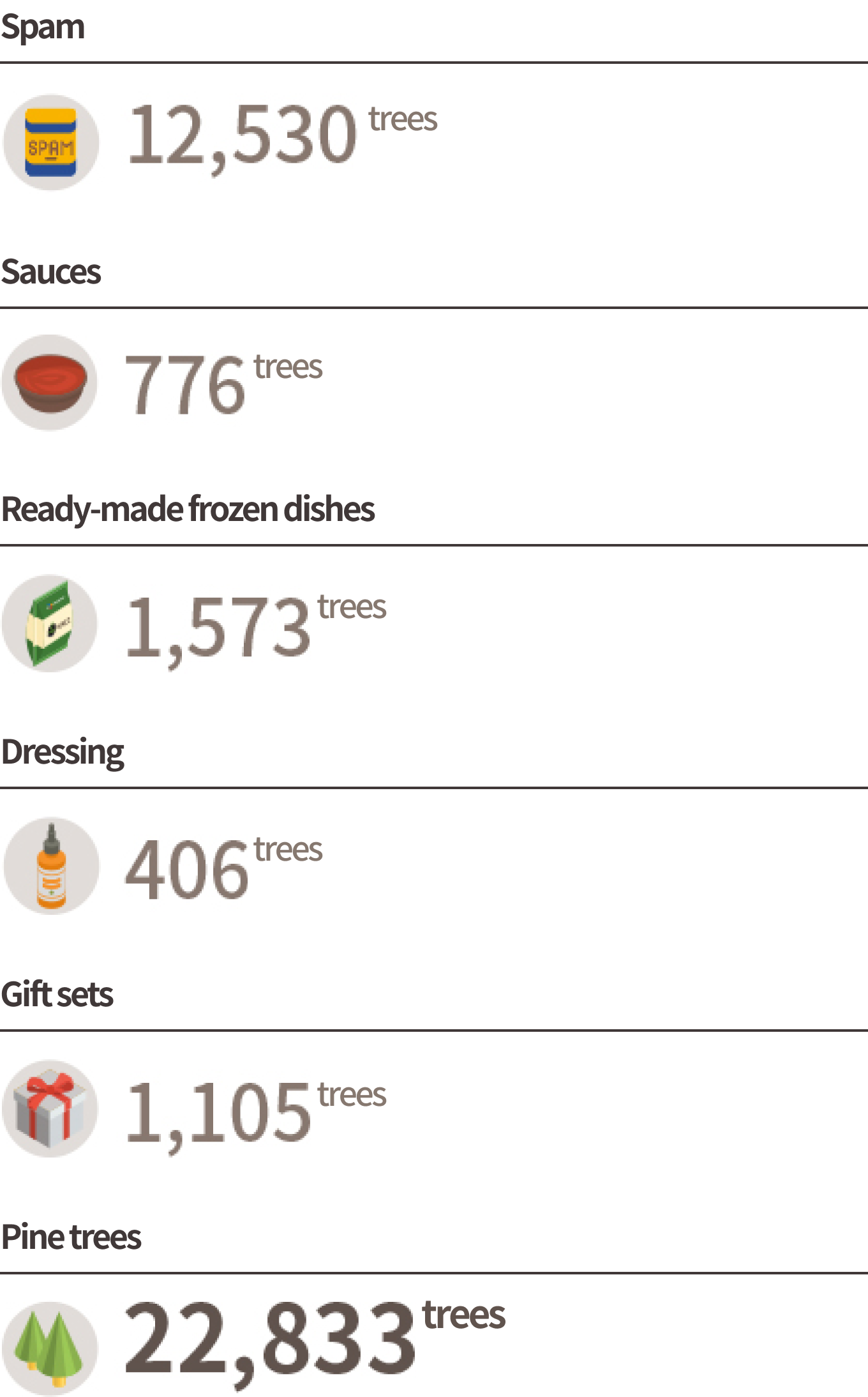

Reduction of GHG emissions from raw plastic materials

Through our sustainable packaging strategy, we reduced 925 tons of plastic and 3,189 tons of GHG emissions in 2021. This is equivalent to planting 22,833 pine trees. The plastic reduction task established in 2020 is ongoing, and by discovering and expanding additional tasks, the cumulative reduction amount is increasing. For foundational improvement, we are working on the Circular Economy Platform task (Label Waste Platform, Holy Grail in Asia research, etc.).

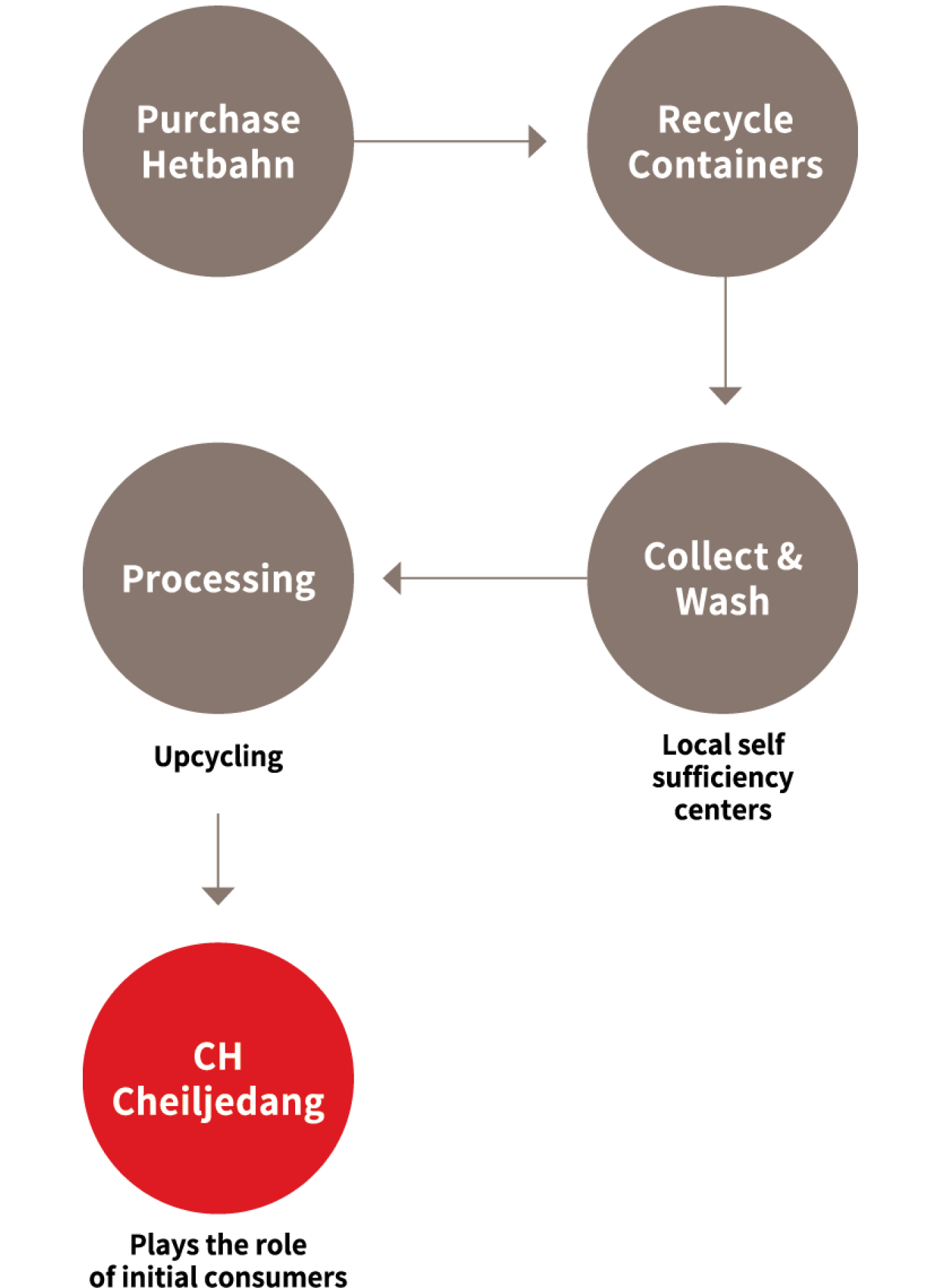

Safe Recycling, collecting Hetbahn containers for plastic resource circulation

We are running ‘Our Containers to save the Earth, Safe Recycling’ campaign as an upcycling project of Hetbahn containers for a self-circulating environment and resource circulation. We have established a system where customers that have purchased Hetbahn through CJ CheilJedang’s online mall, CJ the Market, wash the Hetbahn containers after use, collect them in a box, and apply for free collection service, a local self sufficiency center that is linked to CJ CheilJedang will collect, wash, and processing the containers. After operating the online trial, we plan to install ‘Hetbahn container collection boxes’ at local self sufficiency centers in each region across the country as well as supermarkets. In 2022, we are aiming to reach our goal of collecting 4 million Hetbahn containers by expanding offline collection stations.

Upcycling process of Hetbahn containers

Development of eco-friendly biodegradable plastics

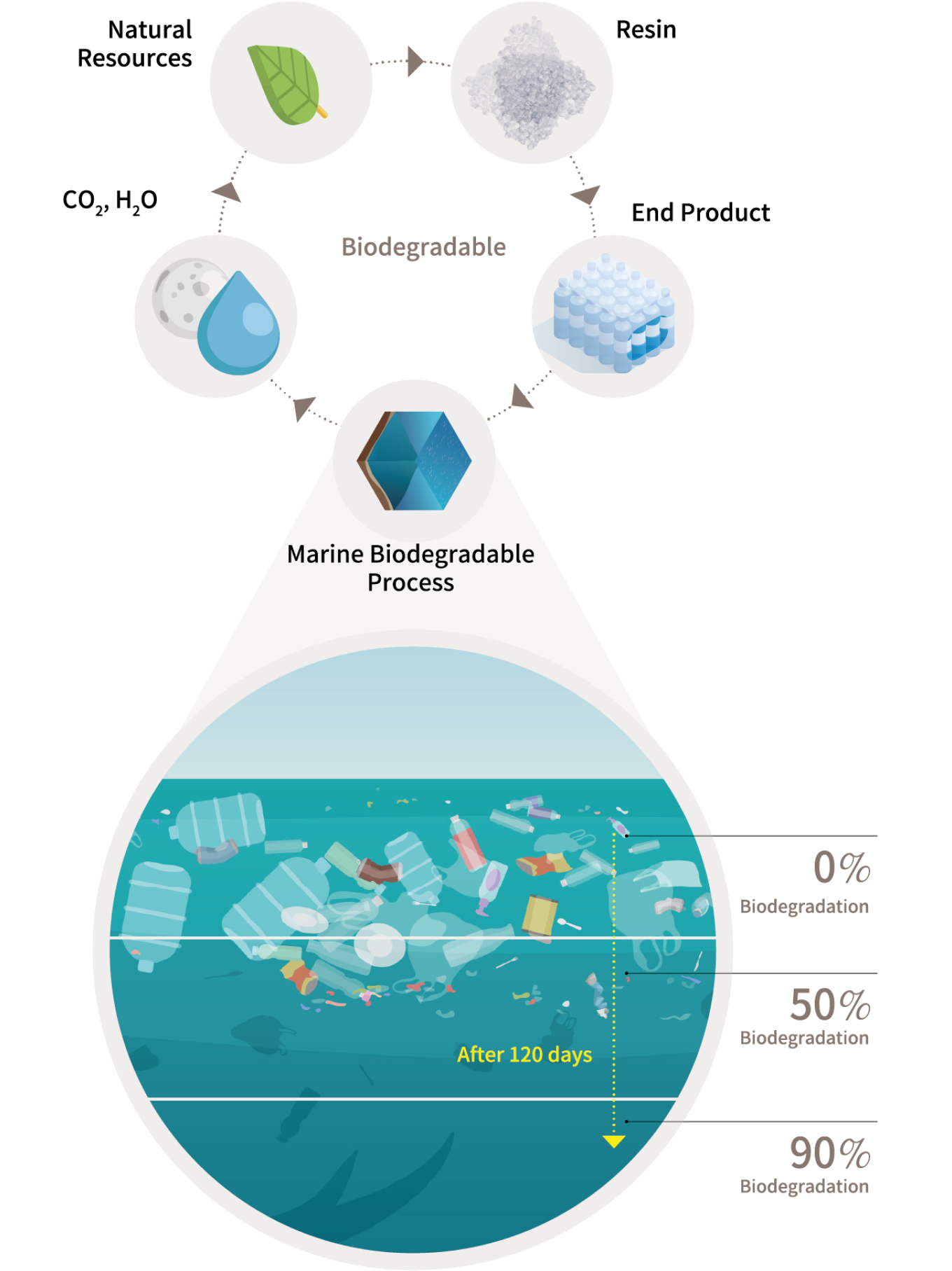

Plastic waste poses a great danger not only to marine ecosystems but also to the whole planet. CJ CheilJedang found the answer to the plastic crisis in 100% BIO-based marine biodegradable plastic called PHA(Polyhydroxyalkanoates). PHA is an eco-friendly plastic material that decomposes in the ocean. It is produced through the process of microorganism fermentation and refinement using plant-derived raw materials such as sugar cane, cassava, and corn, and returns to nature through biodegradation.

PHA Marine Biodegradable Process

PHA is an eco-friendly plastic material that decomposes in waste composting facilities and underground, and even in the ocean within 6 months if the sea temperature between 15 to 40 degrees Celsius. With the material that can be applied to degradable straws, eco-friendly paper coating, packaging materials, agricultural mulching films, fishing nets, etc., we can reduce environmental pollution and create sustainable values for life, the earth and the future.

Applying PHA products

The European Bioplastics Association predicts that the eco-friendly plastics market will grow by 35% from 2020 to 2025. In particular, PHA has a high growth potential not only as an alternative for plastic containers and packaging materials, but because it can also create synergy when combined with various industries such as agriculture, livestock, and pharmaceuticals. Accordingly, CJ CheilJedang built a production facility that produces 5,000 tons of PHA annually in Indonesia in December 2021 and supplies the material to the market. Based on the PHA platform technology, biodegradable polymer derived from BIO, CJ CheilJedang provides high-functional and added eco-friendly solutions through continuous development of various eco-friendly materials/raw material production technologies. Through exploration and convergence of innovative new technologies such as technology using methane and other recycling technology, we are leading the development of next-generation sustainable and eco-friendly technologies.